D&H Industries offers a broad range of press forming capabilities and extensive experience stamping complex metal part designs with deep drawn features.

Our 200, 1,000, and 2,000-ton hydraulic press are capable of deep drawing up to 11 inches in both light and heavy gauge materials. Our hydraulic presses accommodate part diameters that fit within a 96” x 120” press envelope. We also offer a wide range of mechanical presses for shallow drawn parts that can produce medium to high volume parts using progressive dies or one-piece flow processes.

With quick response manufacturing methodologies, we can use our various presses as virtual cells, combining a blank, draw, and pierce operations between 2 or 3 presses to create one piece flow whenever practical. Allowing for deep-drawn part production runs with high volumes and the benefit of cost-saving operations. From small to large finished parts, D&H Industries has the personnel, equipment, and experience to provide highly precise stampings and components to your exact specifications.

Our team of experienced tooling designers and engineers can assist in developing part designs and tooling that eliminate common draw problems like wrinkling and cracking. Send your drawn part designs to D&H Industries, and we will provide cost-effective solutions for your custom applications.

Sheet Metal Forming Process With Rigid Tools

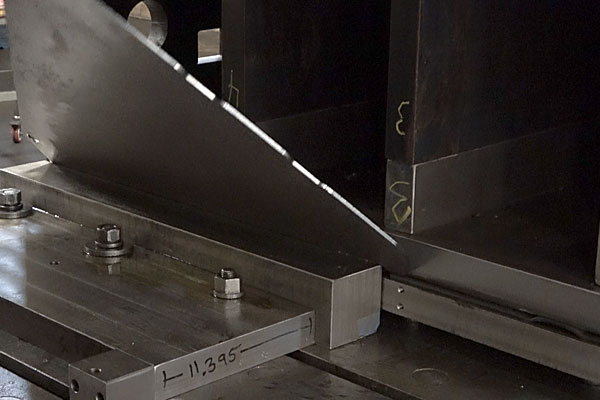

Deep Drawn Component

Deep Drawn Sheet Metal

Deep Drawing Process

Flat Sheet Metal Blank Holder

Mechanical Action of a Punch Press

Stainless Steel Deep Drawn Sink

Drawing Operations