D&H has the capability and expertise to produce medium to high volume production runs of stamped components with our state-of-the-art mechanical presses ranging from 100 to 2,000 tons. Our feed lines handle coil widths up to 42” with annual run quantities from 5,000 to large volumes over 1 million pieces. We stamp small parts weighing less than a 1/4 pound to medium size parts weighing 12 pounds in shallowly drawn shapes to complex forms. We also offer in-die hardware insertion, where our progressive tool engineers have solved how to perform in-die nut insertion to eliminate secondary assembly operations.

D&H has developed a focus factory that specializes in small precision stamped components. We offer more than a dozen presses that range from 100 to 400 tons that can handle material from .015” to .187” thick. Large part progressive stamping occurs at our primary manufacturing location, which features coil-fed stamping presses in 600, 800, and 2,000-ton sizes.

Our press lineup features multiple presses in similar tonnage ranges that provide flexibility in scheduling production runs in various work centers. These presses can also produce cost-effective stamped parts with lower usage by hand-fed processes and automated robotic transfer.

Progressive Die Stamping Video |

In-Die Hardware Insertion Video |

Raw material feeding up to .375” (9.5mm) thick and 42” (1m) wide.

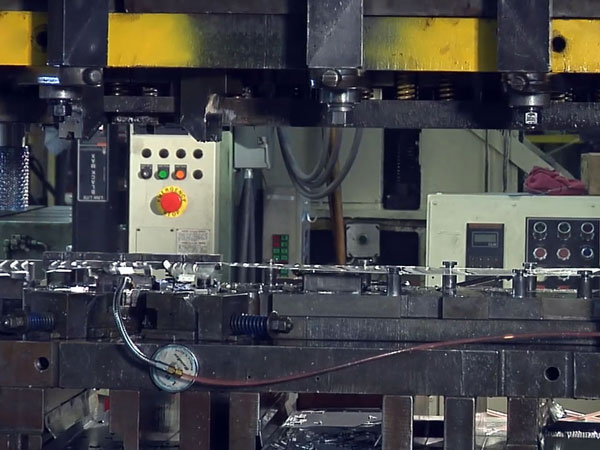

Progressive die stamping is a method of feeding sheet metal in coil or metal strip form between an upper and lower die containing multiple stations. With each stroke of the stamping machine, the material advances through the die set and forming process. Each successive operation in a station produces one or more features by cutting, coining/bending the metal into the desired shape. A progressive die may have between 2 and 20 stations to create finished parts.

Precision Metal Stamping With Tight Tolerances

Progressive Die Stamping Process

Progressive Station to Station Sample

Progressive Metal Stamping Magazines