D&H Industries is a leading producer of metal stamped parts and components for the lawn and garden equipment industry. Major lawn and garden equipment manufacturers (OEMs) trust our stampings, weldments, fabrications, and final assemblies. They demand precise accuracy, high-quality, industrial-strength, part performance, and reliability in every part pressed. And we deliver! We are equipped to produce large deep draw and progressive stampings, heavy weld fabrications, robotic welding, and laser cutting preparation. Part-forming from cold-rolled steel, stainless steel, draw quality steel, sheet metal, brass, aluminum, copper and other high strength materials.

The lawn and garden industry has unique requirements for cosmetic and class A finishes. Types of stamped parts include mower housings, seat decks, engine frames, side panels, bumpers, and grills. Having experience running highly cosmetic stampings, we are very familiar with identifying and mitigating cosmetic requirements, like slugs, dents, and burrs. Likewise, we have familiarity with class A parts as well – from our large presses to your showroom floor.

Many of our large cosmetic stampings are drawn in one of our 1,000-ton hydraulic presses and then formed and further trimmed in one of our 800-ton mechanical presses. Generally, we use 1 piece flow by installing conveyors between large presses. As a result, we can usually gang up our large hydraulic and mechanical presses and have parts drawn, formed, pierced, and trimmed within minutes. Any tool or quality issues are identified immediately.

Our engineering design team possess expert knowledge of metal types and how each reacts to pressure and force. This applied skill results in innovative, quality minded, safe, and cost-effective solutions for metal part product and metal fabrications. We are always available to review and guide you during the design process.

The D&H on-site toolroom is staffed full-time and is responsible for all precision tooling used at our facility. This gives us more quality control and accuracy over our manufacturing process. The immediate response to any tooling issues that may arise reduces production downtime and helps to ensure on-time delivery. We are also experts at adapting existing tooling to our presses.

D&H has two state-of-the-art, ISO 9001 certified manufacturing facilities. We continue to research and invest in lawn and garden equipment metal stamping technology as the industry advances. Our capital equipment acquisitions have positioned the company to manage large stamping and fabrication projects that many shops simply cannot.

Lawn and Garden Stamped Parts

Mower Deck Stamping Process

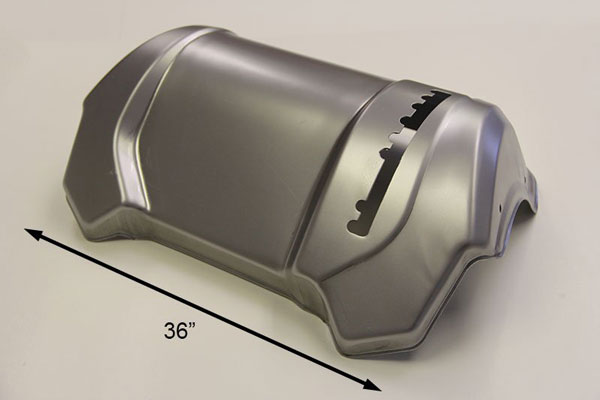

Finished Mower Deck Stamping

Lawn Tractor Seat Deck

Mower Deck Fabrication Weldment

Assembled Stamped Lawn Mowers

Snow Blower Stamped Weldment

Our manufacturing capabilities for lawn and garden components exceed our customer’s standards when it comes to strength, rigidity, and precision. We work closely with each client so every job is exactly what you need for your particular project, specializing in tough deep draws, large parts, and large runs.

D&H has been successful with prototyping new parts, as well as re-engineering existing designs to potentially lower the weight of the finished product and decrease production costs. We can also accommodate seasonal product demands and understand that speed to market is crucial. Utilize our services to ensure your parts are ready when you need them.

Other Industries Served: Aerospace, Agricultural, Automotive, Defense, Electrical, Electronics, Energy, Furniture, Heavy Equipment, Industrial, Lawn and Garden, Military, Mining, Railway, Solar, Transportation, and Truck