Our metal stamping production is from a wide range of materials, including cold-rolled steel, stainless steel, draw quality steel, brass, aluminum, copper, corrosion resistance, and high-strength materials from metal sheets and coils. We manufacture high-quality parts and components for a multitude of industries.

We work with materials that range in thickness from .005” (.127 mm) up to .5” (13 mm) and die configurations that range from the simple to complex in design nature. These factors guide us in determining the proper punch press used for production from our numerous options. We are also capable of handling coils up to 45” (1143 mm) in width from our feeding system.

Press capacities range from 32-ton to 800-ton mechanical presses and from 500-ton to 2000-ton hydraulic presses. Our recent expansion of new hydraulic and straight side presses has given us even greater flexibility when choosing the most appropriate equipment to manufacture the required specs for your application needs.

Our tool and die department are experts at adapting existing stamping and progressive dies to our presses.

| Metal Stamping Techniques and Forming Processes |

Large Stamping Press

Hand Transfer Multiple Die Gang Tool

Stainless Steel Stamped Rings

Progressive Stamped Radiator Fins

Progressive Steel Alloy Stamping

Progressive Metal Stamping Bent

Various Materials Stampings

Flat Sheet Metal Panel Stamping

Complicated Metal Components Stamping

Heavy-Duty Stamped Motor Mounts

Punch Bucket Panels

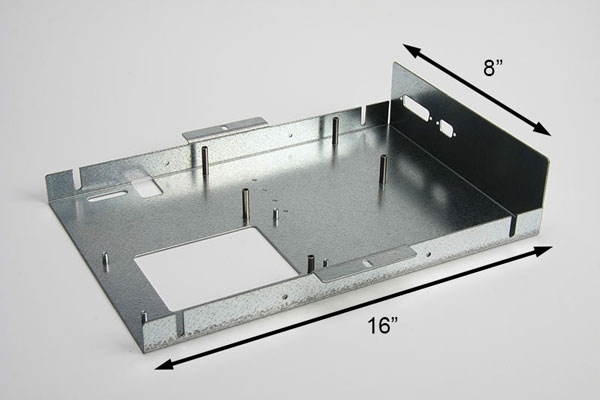

Galvanized Stamped Steel Panel